Vertikales Bearbeitungszentrum

Underground utility tunnel systems, also known as comprehensive utility corridors or integrated utility tunnels, are vital components of modern urban infrastructure. These systems house and protect a wide array of utilities such as electricity, telecommunications, water supply, gas, heating, and drainage. To ensure safe, efficient, and long-lasting access to these networks, ductile iron covers are widely used as access points in these tunnel systems.

Ductile iron, also referred to as nodular cast iron, combines the castability of gray iron with the strength and ductility of steel. These properties make ductile iron covers ideal for high-performance environments like utility tunnels, where both structural integrity and durability are critical. One of the key advantages is their high load-bearing capacity, making them suitable for areas with vehicle or equipment traffic. Their excellent impact resistance helps prevent cracking or damage during maintenance or in the event of heavy external loads.

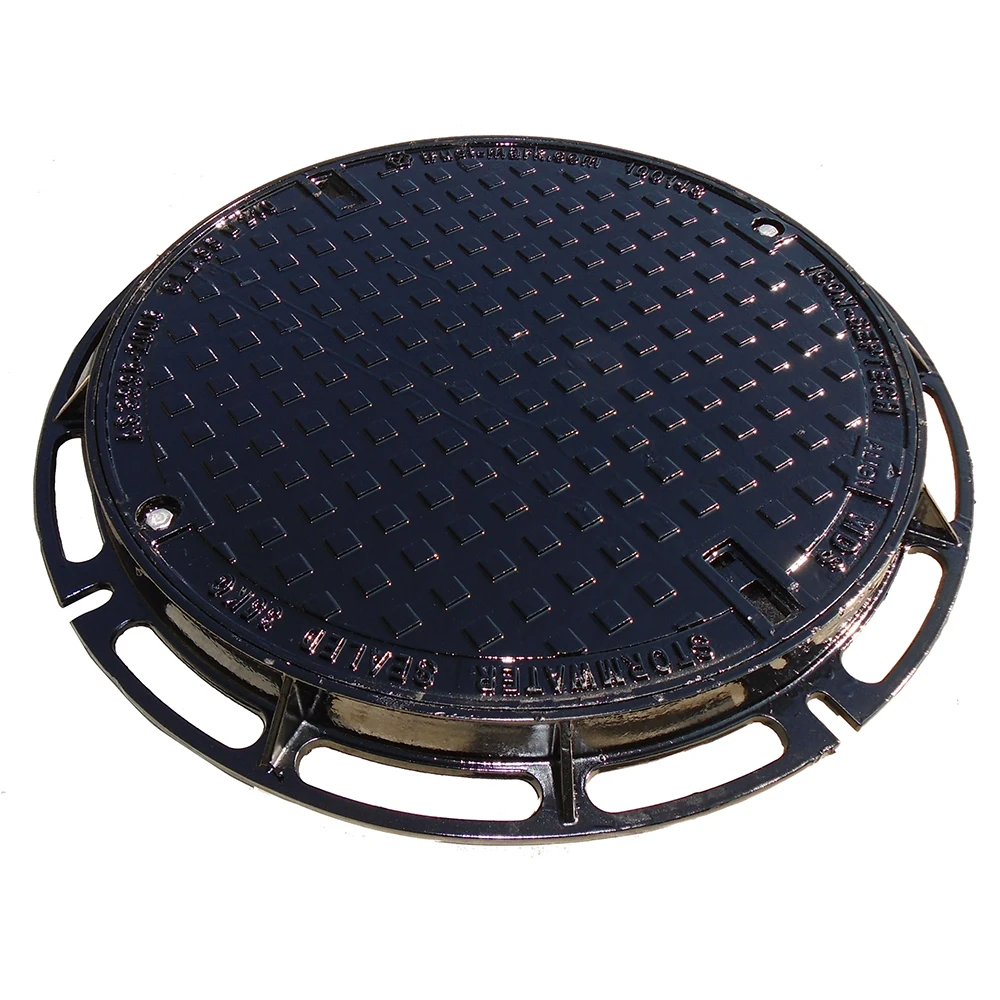

In underground utility tunnel systems, ductile iron covers are typically installed at key locations for inspection and maintenance purposes. These covers provide secure and repeatable access to buried services while protecting against unauthorized entry. Their precision-manufactured sealing systems (often with rubber gaskets or locking mechanisms) can also offer water and gas tightness, which is essential in preventing contamination or gas leakage—especially in tunnels containing flammable utilities like natural gas.

Another key benefit is the long service life of ductile iron covers. Resistant to corrosion, thermal expansion, and chemical exposure, they can perform reliably in the often humid and chemically active environments of utility tunnels. Surface treatments such as epoxy coatings or hot-dip galvanization further enhance their corrosion resistance, reducing the need for frequent replacement or repair.

From a safety perspective, ductile iron covers can also be designed with anti-slip surfaces and locking systems, ensuring safe operation for maintenance personnel and minimizing the risk of accidents. Custom markings or embedded smart chips can be added for asset tracking and digital management as part of a smart city infrastructure initiative.

In summary, ductile iron covers play a crucial role in the successful operation and maintenance of underground utility tunnel systems. Their combination of mechanical strength, environmental resistance, and adaptability to smart technologies makes them a dependable and efficient solution for modern cities looking to optimize infrastructure reliability and safety.