We specialize in manufacturing high-quality municipal manhole covers designed to meet stringent industry standards. Our products are engineered for durability, load-bearing capacity, and corrosion resistance, making them ideal for city planners, construction firms, and utility providers worldwide.

Manhole covers play a critical role in urban infrastructure by:

✔ Ensuring Public Safety – Preventing accidental falls into underground chambers.

✔ Protecting Utility Systems – Keeping water, debris, and pests out of critical infrastructure.

✔ Facilitating Maintenance Access – Allowing easy entry for repairs and inspections.

✔ Supporting Heavy Traffic Loads – Withstanding the weight of vehicles, including trucks and buses.

✔ Enhancing Longevity of Underground Networks – Reducing wear and tear on pipes and cables.

A poorly designed or low-quality manhole cover can lead to accidents, increased maintenance costs, and infrastructure failures. That’s why choosing a reliable municipal manhole cover supplier is crucial.

1. Premium Materials for Maximum Durability

Our municipal manhole covers are manufactured using:

Ductile Iron – Offers superior strength and impact resistance.

Cast Iron – Traditional choice with excellent wear resistance.

Composite Materials – Lightweight yet durable, ideal for pedestrian zones.

Stainless Steel & Galvanized Steel – Corrosion-resistant for harsh environments.

Each material is selected based on load requirements, environmental conditions, and cost-efficiency.

2. High Load-Bearing Capacity

We design our manhole covers to comply with EN 124, ASTM A48, and other international standards, ensuring they can handle:

Pedestrian Traffic (Class A) – Parks, sidewalks.

Light Vehicles (Class B) – Residential areas, parking lots.

Heavy Traffic (Class C & D) – Roads, highways.

Extra Heavy-Duty (Class E & F) – Airports, industrial zones.

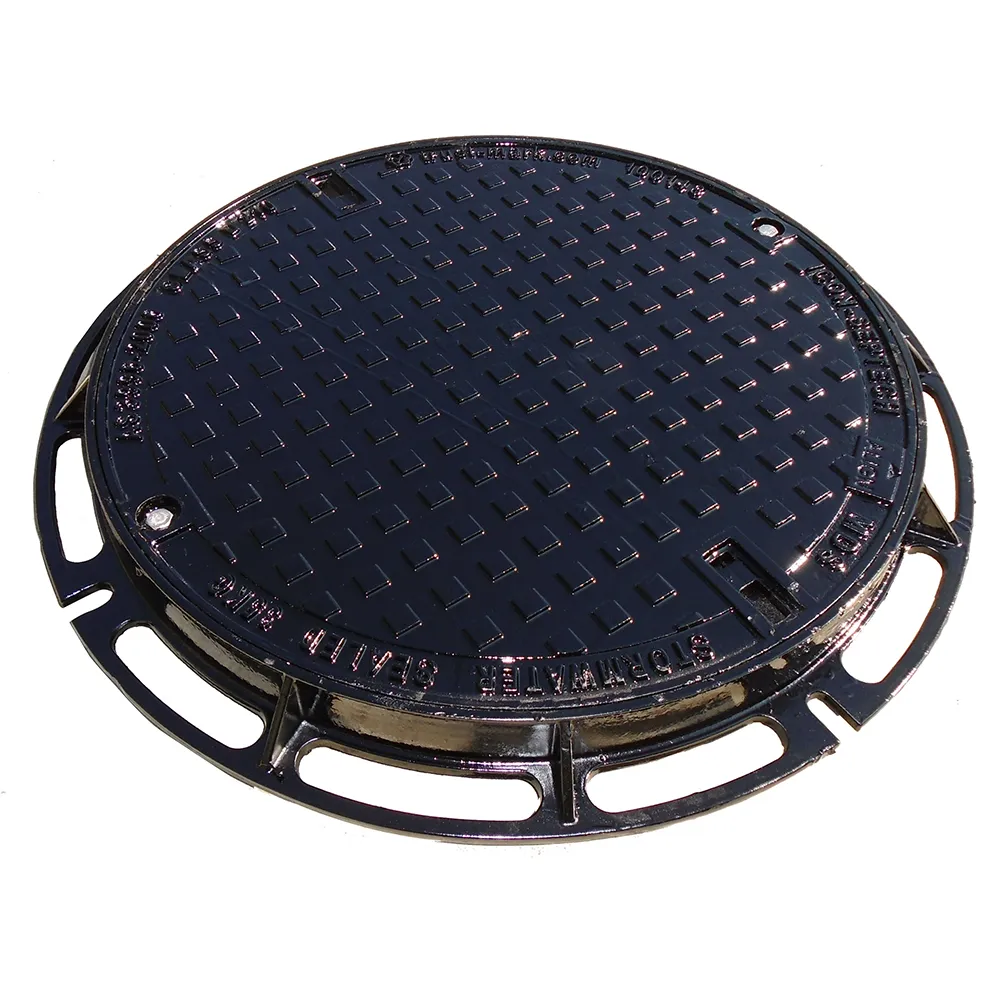

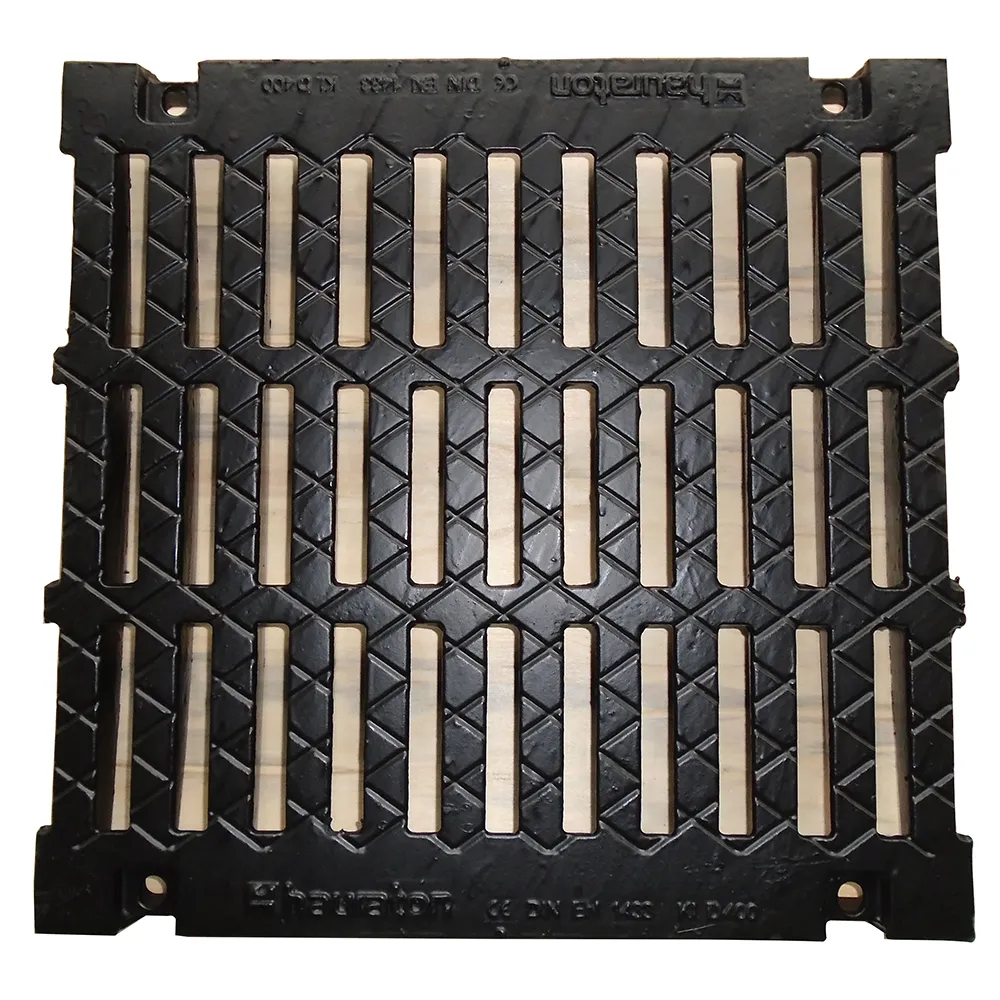

3. Anti-Slip & Safety Features

Safety is a top priority. Our covers include:

Patterned or Checkered Surfaces – Prevents slipping in wet conditions.

Locking Mechanisms – Deters theft and unauthorized access.

Lifting Holes or Keys – Ensures easy and safe removal.

4. Corrosion & Weather Resistance

Our manhole covers are treated with:

Epoxy Coatings – Protects against rust and chemicals.

Hot-Dip Galvanization – Extends lifespan in coastal or high-moisture areas.

Polymer Coatings – Ideal for wastewater and acidic environments.

5. Noise Reduction Technology

To minimize clanging sounds when vehicles pass over them, we offer:

Rubber Seals – Reduces metal-to-metal contact.

Composite Designs – Quieter than traditional metal covers.

6. Customizable Designs & Branding

We provide:

Custom Sizes & Shapes (Round, Square, Rectangular).

City Logos or Identification Markings – For municipal branding.

Color Options – To blend with urban aesthetics.

Our manhole covers are used in various infrastructure projects, including:

1. Road & Highway Systems

Withstands heavy vehicle loads.

Ensures smooth traffic flow with minimal noise.

2. Sewage & Stormwater Drainage

Prevents blockages and flooding.

Resists corrosion from wastewater.

3. Electrical & Telecommunication Access

Protects underground cables.

Allows easy maintenance access.

4. Pedestrian Zones & Public Spaces

Lightweight yet durable for foot traffic.

Enhances urban aesthetics.

5. Industrial & Airport Tarmacs

Supports extreme weights (aircraft, heavy machinery).

High resistance to fuel and chemical exposure.

Long Lifespan – Engineered to last decades with minimal maintenance.

Safety Compliance – Meets EN 124, OSHA, ISO 9001 standards.

Cost-Effective – Reduces replacement and repair expenses.

Eco-Friendly Options – Recyclable materials available.

Global Supply – Available for export with reliable logistics.