Drain Covers For Sale: Storm, Access & All Types

The Critical Role and Evolution of Drain Covers in Modern Infrastructure

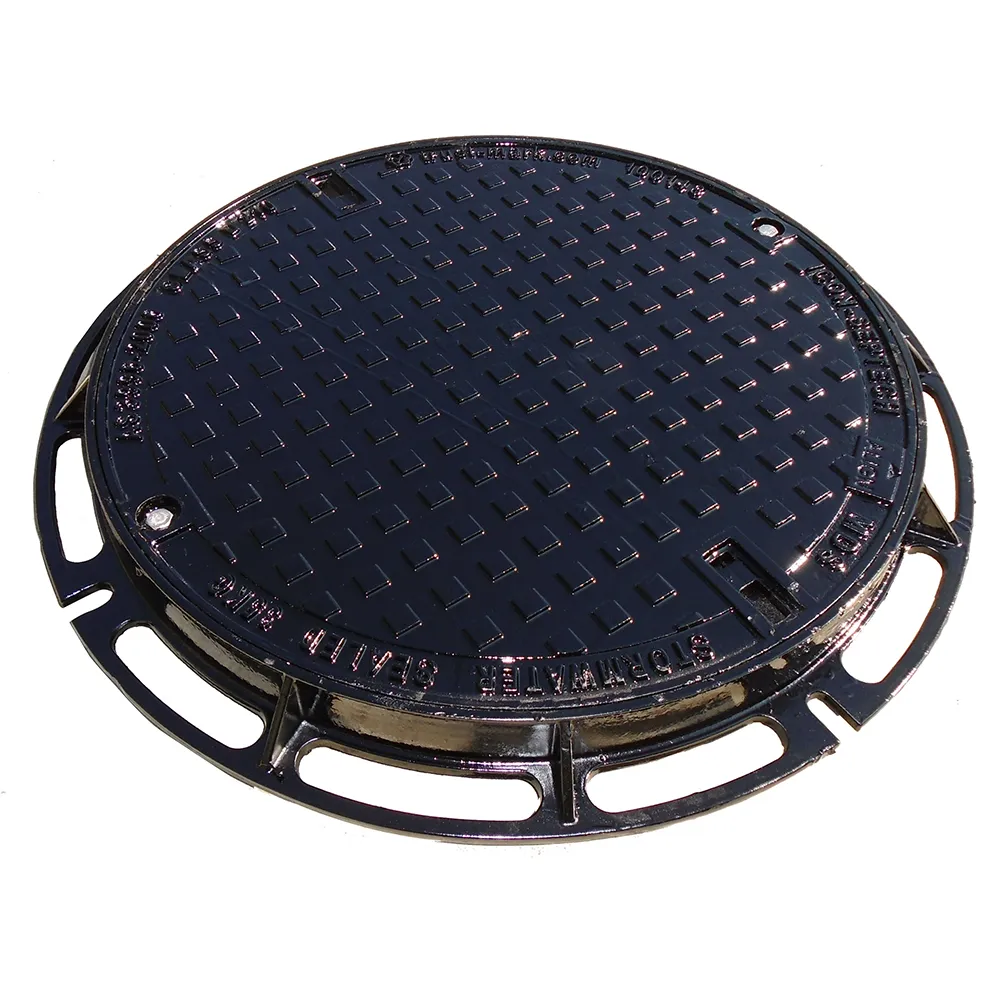

In the intricate landscape of urban and industrial infrastructure, the integrity of utility systems hinges significantly on robust components. Among these, drain covers for sale play a pivotal role in ensuring safety, functionality, and longevity of underground networks. These essential components prevent debris accumulation, provide secure access for maintenance, and safeguard pedestrians and vehicles from open shafts. The market for these covers is evolving rapidly, driven by stringent regulatory standards, an increasing demand for sustainable materials, and the integration of smart city technologies. Understanding the various types, manufacturing processes, and application benefits is crucial for B2B decision-makers seeking reliable and compliant solutions for their projects, whether it's for municipal drainage, industrial facilities, or specialized utility access.

Modern infrastructure demands not just functional components but also those that offer enhanced durability, corrosion resistance, and specific load-bearing capacities. The shift towards lightweight yet strong composite materials, alongside advancements in traditional cast iron and ductile iron technologies, reflects an industry-wide commitment to superior performance. Furthermore, the emphasis on security features, anti-theft designs, and ergonomic handling for maintenance crews highlights a holistic approach to product development. This comprehensive approach ensures that the chosen drain cover not only meets immediate project specifications but also contributes to long-term operational efficiency and public safety, ultimately reducing total cost of ownership over its extensive service life.

Navigating Industry Trends: Focus on Storm Drain Covers and Material Innovation

The demand for high-performance drain covers for sale is significantly influenced by global infrastructure development and the increasing frequency of extreme weather events. Specifically, the market for storm drain covers for sale is experiencing substantial growth as urban areas invest in enhanced stormwater management systems. These covers are designed to handle significant water flow, filter debris, and withstand heavy vehicular loads, making material selection paramount. Ductile iron, known for its superior strength-to-weight ratio and elasticity compared to traditional gray cast iron, has become a preferred material. Its microstructural properties, characterized by spherical graphite nodules, prevent crack propagation, offering exceptional resistance to impact and fatigue, which is crucial for applications under dynamic loads such as heavy traffic areas.

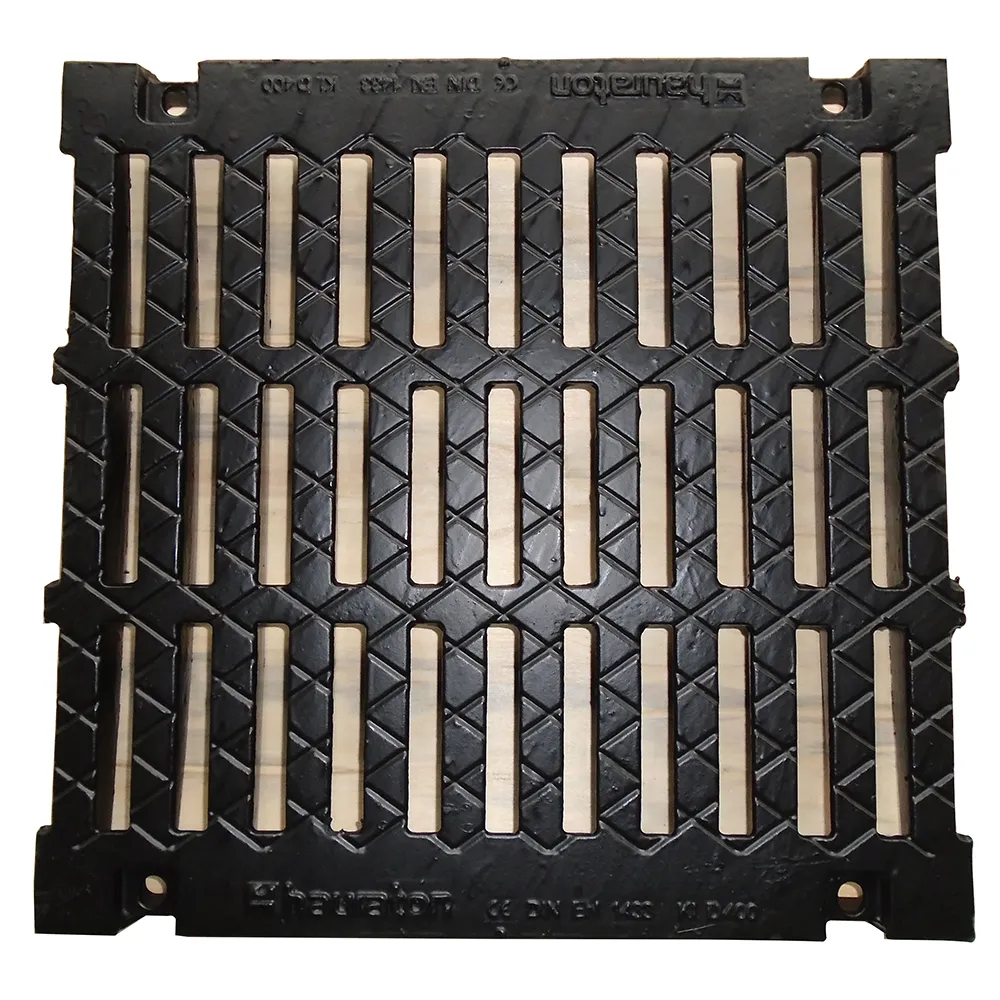

Beyond ductile iron, composite materials are gaining traction due to their lightweight properties, resistance to corrosion, and anti-theft characteristics. These composites, often reinforced with fiberglass or other synthetic fibers, offer excellent load-bearing capabilities while being significantly lighter, simplifying installation and reducing transportation costs. For example, a typical D400 composite cover might weigh 50% less than its ductile iron counterpart, reducing manual handling risks. Additionally, the integration of smart sensor technology into drain covers is an emerging trend, enabling real-time monitoring of water levels, flow rates, and structural integrity, thereby contributing to predictive maintenance strategies and optimized urban water management. These innovations are reshaping the landscape of utility access solutions, pushing the boundaries of traditional design and functionality for all drain covers for sale.

Understanding Types of Drain Covers and Technical Specifications

When considering drain covers for sale, it's essential to differentiate between the various types of drain covers available, each designed for specific applications and load requirements. The European standard EN 124 categorizes these covers based on their load-bearing capacity, ranging from A15 (pedestrian areas) to F900 (airport runways). For instance, B125 covers are suitable for footways and light vehicle traffic, while D400 covers are engineered for roadways and parking areas. Materials commonly include cast iron, ductile iron, concrete, and composite materials, each offering distinct advantages in terms of strength, weight, corrosion resistance, and cost-effectiveness. The selection process must align with the anticipated traffic loads, environmental conditions, and specific regulatory compliance for the installation site to ensure optimal safety and performance. This detailed understanding helps in specifying the correct solution from the range of different types of drain covers.

Key Technical Parameters for Drain Covers

| Parameter | Description | Typical Range/Value | Standard |

|---|---|---|---|

| Load Class (EN 124) | Defines load-bearing capacity in kN. | A15 (15kN) to F900 (900kN) | EN 124-2:2015 |

| Material | Primary material composition. | Ductile Iron (GGG50), Grey Cast Iron, Composites (FRP), Steel | ISO 1083 (Ductile Iron) |

| Clear Opening (CO) | The internal diameter or dimension of the opening. | 300mm to 1000mm (standard) | Manufacturer Spec |

| Frame Dimensions | Overall external dimensions of the frame. | Varies by CO | Manufacturer Spec |

| Surface Coating | Protection against corrosion. | Bitumen coating, Epoxy paint, Galvanization | ISO 12944 |

| Lifespan Expectancy | Estimated operational life under typical conditions. | 30-50+ years for Ductile Iron | Industry Best Practice |

The distinction between different types of drain covers for sale also extends to their design features, such as anti-slip surfaces, locking mechanisms for security, and ventilation slots for gas release. For example, specific designs for an access chamber cover might prioritize ease of opening for regular inspections, while a heavy-duty sewer cover would emphasize robust security against unauthorized access. Understanding these nuances is critical for engineers and procurement specialists to ensure the selected product not only fits the physical space but also performs optimally under expected operational stresses and environmental conditions, guaranteeing compliance with safety regulations and functional longevity.

Precision Engineering: The Manufacturing Process of Municipal Manhole Covers

The manufacturing of high-quality Municipal Manhole Covers, a significant segment of drain covers for sale, involves a meticulous and technically advanced process, primarily utilizing casting techniques for materials like ductile iron. This process begins with the design phase, where engineers leverage CAD software to create precise models, ensuring compliance with international standards such as ISO 9001 for quality management and EN 124 for load classifications. Following design, pattern making involves creating exact replicas of the cover and frame in wood or resin, which are then used to form molds in sand. This initial stage dictates the dimensional accuracy and surface finish of the final product, emphasizing the importance of precision engineering from the outset.

Key Manufacturing Stages:

- Material Preparation & Melting: High-grade raw iron, steel scrap, and alloying elements (like magnesium for ductile iron spheroidization) are precisely measured and melted in induction furnaces. Temperature control and chemical composition analysis (e.g., carbon equivalent testing) are critical at this stage to achieve the desired material properties, such as tensile strength and elongation, as per ASTM A536 Grade 65-45-12 for ductile iron.

- Molding & Casting: Molten metal is poured into sand molds, which are prepared using automated molding lines to ensure consistency and efficiency. The sand casting process allows for complex geometries and large production volumes. Proper gating and risering systems are designed to ensure complete mold filling and minimize casting defects like shrinkage or porosity.

- Cooling & Shakeout: After casting, the components are allowed to cool gradually to prevent thermal stresses. Once solidified, the castings are removed from the sand molds in a process called shakeout. The sand is then reclaimed and reused, promoting sustainability in the manufacturing cycle.

- Fettling & Finishing: Excess material, such as risers and gates, is removed from the castings using grinding and cutting tools. This is followed by shot blasting to clean the surface and improve aesthetics. For precision components, CNC machining may be employed to achieve exact dimensions for sealing surfaces or locking mechanisms, ensuring a tight fit and optimal performance of the drain covers for sale.

- Quality Control & Testing: Each Municipal Manhole Cover undergoes rigorous quality checks. This includes visual inspection for surface defects, dimensional checks using precision gauges, and material property verification through spectrographic analysis. Load testing, as per EN 124, involves applying specific forces to prototypes to confirm load-bearing capacity. Additionally, non-destructive testing (NDT) methods like ultrasonic testing might be used to detect internal flaws.

- Coating & Packaging: Finally, covers are coated with protective layers, typically bitumen or epoxy paints, to enhance corrosion resistance, extending the product's lifespan, especially in harsh environments like petrochemical or wastewater treatment plants. Products are then carefully packaged for transport to ensure their integrity upon arrival at the project site.

This comprehensive manufacturing approach, integrating advanced technology with strict quality control, ensures that each of the drain covers for sale not only meets but often exceeds industry standards, providing reliable, long-lasting solutions for critical infrastructure applications.

Application Scenarios and Technical Advantages

The versatility of modern drain covers for sale allows their deployment across a myriad of industrial and municipal applications, where their specific technical advantages translate into significant operational benefits. In the petrochemical industry, for example, specialized access covers crafted from corrosion-resistant ductile iron or advanced composites are crucial for securing underground pipelines and valves. Their robust design prevents unauthorized access and protects against chemical spills, while ventilation features can mitigate hazardous gas buildup. In metallurgy, heavy-duty covers with high load ratings (e.g., E600 or F900) are essential for industrial zones where heavy machinery and vehicles operate, ensuring the integrity of utility access points under extreme stress.

For municipal water and drainage systems, the benefits extend beyond mere access. Advanced storm drain covers for sale often feature integrated grates designed to filter out large debris, preventing blockages in the sewer network and reducing maintenance frequency. This contributes directly to energy savings by ensuring unimpeded water flow and preventing pump overloads. The precise fit and non-rocking design of high-quality covers significantly reduce noise pollution in urban environments, enhancing quality of life. Furthermore, specialized finishes, such as non-slip coatings, enhance safety for pedestrians and cyclists, illustrating a holistic approach to public infrastructure that integrates functional performance with societal well-being. For a mini access chamber cover in a residential area, these same principles apply on a smaller scale, ensuring durability and safety.

Beyond durability, the long service life of high-quality drain covers for sale, often exceeding 50 years for ductile iron products, contributes substantially to reduced lifecycle costs. This longevity minimizes the need for frequent replacements, lowering material, labor, and disposal expenses over time. Manufacturers committed to ISO and ANSI standards ensure consistent product quality, reducing the risk of premature failure. This long-term reliability is a key technical advantage, as it directly impacts the sustainability and economic viability of large-scale infrastructure projects. Investing in superior quality means investing in a future-proof solution that delivers consistent performance under varying environmental and operational conditions.

Choosing Your Supplier: Manufacturer Comparison and Custom Solutions

Selecting the right manufacturer for drain covers for sale is a critical decision for any B2B project, impacting product quality, delivery timelines, and overall project costs. Key factors to consider include the manufacturer's adherence to international standards (e.g., ISO 9001, EN 124), their experience in the industry, production capacity, and capability for providing custom solutions. A reputable manufacturer, like Kaihua Casting, demonstrates expertise not only in standard product lines but also in engineering bespoke solutions for unique infrastructure challenges. This includes developing specialized designs for an access chamber cover with specific dimensions or creating aesthetic surface patterns for public spaces, ensuring both functionality and visual integration.

Manufacturer Comparison: Key Considerations

| Factor | Why it Matters | Kaihua Casting's Approach |

|---|---|---|

| Certifications & Standards | Ensures product quality, safety, and compliance (e.g., EN 124, ISO 9001). | ISO 9001 certified, products meet EN 124, ANSI, and local standards. |

| Material Expertise | Impacts durability, load capacity, and corrosion resistance. | Specialized in high-grade ductile iron, offering superior strength and longevity. |

| Customization Capabilities | Ability to meet unique project requirements (dimensions, logos, designs). | Extensive R&D and manufacturing flexibility for bespoke designs. |

| Production Capacity & Lead Time | Ensures timely delivery for large-scale projects. | Modern casting facilities ensure efficient, on-time production and delivery. |

| Technical Support & After-Sales | Assistance with selection, installation, and problem-solving. | Dedicated technical team, comprehensive warranty, responsive customer service. |

Custom solutions are particularly valuable for urban renewal projects or specialized industrial installations where off-the-shelf drain covers for sale may not suffice. This could involve designing a unique mini access chamber cover for limited spaces, incorporating specific utility company logos, or even engineering complex multi-part covers for large utility trenches. A manufacturer with in-house design and prototyping capabilities can significantly streamline this process, offering rapid iteration and precise execution. This ability to tailor products precisely to client needs, backed by robust engineering and quality control, ensures that the chosen solution performs optimally and integrates seamlessly into the broader infrastructure, offering long-term value and reliability.

Real-World Impact: Application Cases and Client Trust

The true measure of quality for drain covers for sale lies in their performance within real-world application scenarios and the subsequent feedback from clients. Our Municipal Manhole Covers have been successfully deployed in a diverse range of projects globally, demonstrating their reliability and adherence to stringent performance criteria. For instance, in a major urban infrastructure upgrade project in City X, over 5,000 D400 ductile iron covers were installed along arterial roads. The project required covers with exceptional load-bearing capacity and a non-rocking design to minimize noise and ensure vehicle safety. Post-installation reports confirmed significant improvements in road surface stability and reduced maintenance calls for cover adjustments, directly attributing to the superior design and manufacturing quality.

Another notable case involves a large industrial complex in Region Y, where a significant number of specialized access chamber cover units were required for a new petrochemical facility. Due to the corrosive environment and the need for restricted access, the client specified covers made from highly corrosion-resistant ductile iron with bespoke locking mechanisms. Our technical team collaborated closely with the client's engineers to design and produce covers that not only met the exact technical specifications but also integrated advanced security features. The client's feedback highlighted the seamless integration, the product's robust performance under demanding industrial conditions, and the superior corrosion resistance, ensuring long-term operational integrity and safety for their critical infrastructure.

These successful applications underscore our commitment to delivering not just products, but comprehensive solutions. Our long-standing service record, spanning over two decades in the casting industry, is built upon a foundation of trust and consistent delivery of high-performance drain covers for sale. We continuously gather client feedback to refine our products and services, ensuring that we remain at the forefront of innovation and quality in municipal and industrial casting solutions. This iterative process of design, deployment, and feedback allows us to maintain the highest levels of trustworthiness and authority in the global market, providing peace of mind to our B2B partners.

Frequently Asked Questions (FAQ)

Q1: What is the typical delivery period for large orders of drain covers for sale?

A1: Our standard lead time for large orders of Municipal Manhole Covers or other drain covers for sale typically ranges from 4 to 8 weeks, depending on the order volume, specific customization requirements, and current production schedules. We utilize advanced production planning systems to optimize efficiency and minimize delays. For urgent projects or large-scale procurements, we encourage early communication with our sales team to discuss expedited manufacturing and logistics options. Our robust supply chain management ensures reliable and timely delivery to global destinations.

Q2: What kind of warranty do you offer on your Municipal Manhole Covers?

A2: We stand behind the quality and durability of our products. All our Municipal Manhole Covers and other drain covers for sale come with a comprehensive warranty against manufacturing defects and material failures under normal usage conditions. The specific terms and duration of the warranty may vary based on product type and application, typically ranging from 5 to 10 years. Detailed warranty information is provided with each product quotation and can be reviewed by contacting our customer support team. Our commitment extends to providing comprehensive support throughout the product's lifecycle.

Q3: Can your drain covers be customized for specific applications, such as a mini access chamber cover or with unique logos?

A3: Absolutely. Customization is a core strength of our service offering. We can produce drain covers for sale tailored to specific dimensions, load requirements, and aesthetic preferences. This includes specialized designs for a mini access chamber cover in constrained spaces, incorporating client or municipal logos, specific drainage patterns, or unique locking mechanisms for enhanced security. Our in-house engineering and design team works closely with clients from concept to production, ensuring that the customized product precisely meets their functional and branding requirements while adhering to all relevant industry standards.

Q4: How do your drain covers contribute to environmental sustainability?

A4: Our focus on sustainable manufacturing and product design ensures our drain covers for sale contribute positively to environmental goals. We primarily use ductile iron, a highly recyclable material, reducing the demand for virgin resources. Our manufacturing processes incorporate energy-efficient techniques and waste reduction strategies, including sand reclamation in our casting foundries. Furthermore, the exceptional longevity of our covers minimizes the need for replacements, reducing material consumption and waste generation over their operational lifespan. By providing durable and efficient solutions, we help infrastructure projects achieve their long-term sustainability objectives.

Why Choose Kaihua Casting for Your Drain Cover Needs

Choosing Kaihua Casting for your drain covers for sale means partnering with a proven leader in the B2B casting industry. With decades of specialized experience in producing high-quality Municipal Manhole Covers and related access solutions, we combine traditional craftsmanship with advanced manufacturing technologies. Our commitment to excellence is reflected in every product, rigorously tested to meet or exceed international standards like EN 124, ISO 9001, and ANSI. We understand the critical importance of reliable infrastructure components and are dedicated to providing solutions that offer unparalleled durability, security, and long-term cost-effectiveness. Our ductile iron products are designed for maximum resilience in diverse operational environments, from heavy-duty industrial applications to standard municipal road networks.

Our client-centric approach ensures comprehensive support from initial consultation through to after-sales service. We offer flexible customization options, allowing engineers and procurement managers to specify the exact parameters for their projects, whether it’s a standard storm drain covers for sale or a bespoke access chamber cover. Our robust production capacity ensures timely delivery, even for large-scale orders, mitigating project delays and maintaining operational continuity. At Kaihua Casting, we don't just supply products; we forge lasting partnerships, providing expert guidance, innovative solutions, and unwavering support to help our clients build resilient and sustainable infrastructure. This dedication to quality, expertise, and customer satisfaction makes us the preferred choice for discerning B2B partners worldwide.

References

- European Committee for Standardization. EN 124-2:2015 - Gully tops and manhole tops for vehicular and pedestrian areas - Part 2: Gully tops and manhole tops made of ductile iron.

- International Organization for Standardization. ISO 9001:2015 - Quality management systems — Requirements.

- American Society for Testing and Materials. ASTM A536-84 (2019) - Standard Specification for Ductile Iron Castings.

- American National Standards Institute. ANSI/AWWA C207-18 - Flanges for Waterworks Service, Sizes 4 In. Through 144 In. (100 mm Through 3,600 mm).

- The Ductile Iron Pipe Research Association (DIPRA). Ductile Iron Pipe Design and Manufacturing Guide.