Premium Drain Covers for Sale: Storm, Access & All Types

Understanding the Evolving Landscape of Drain Covers for Sale

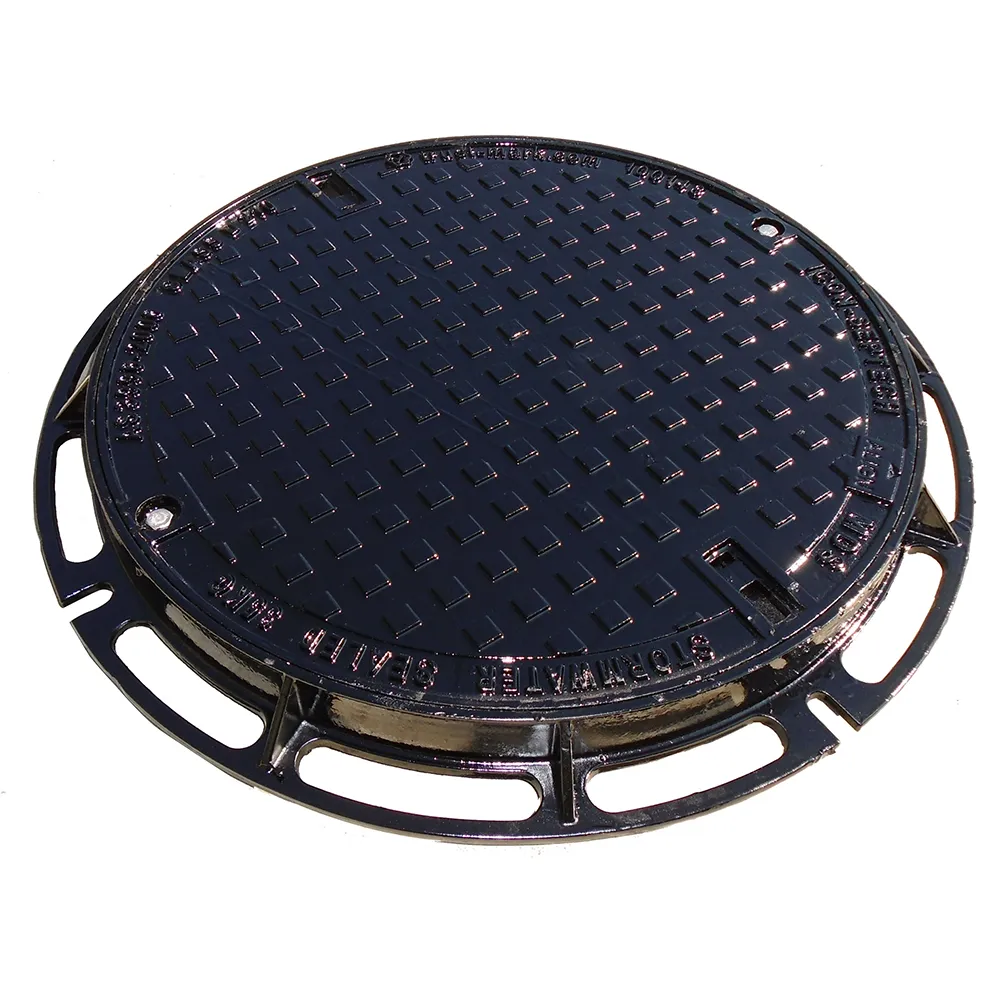

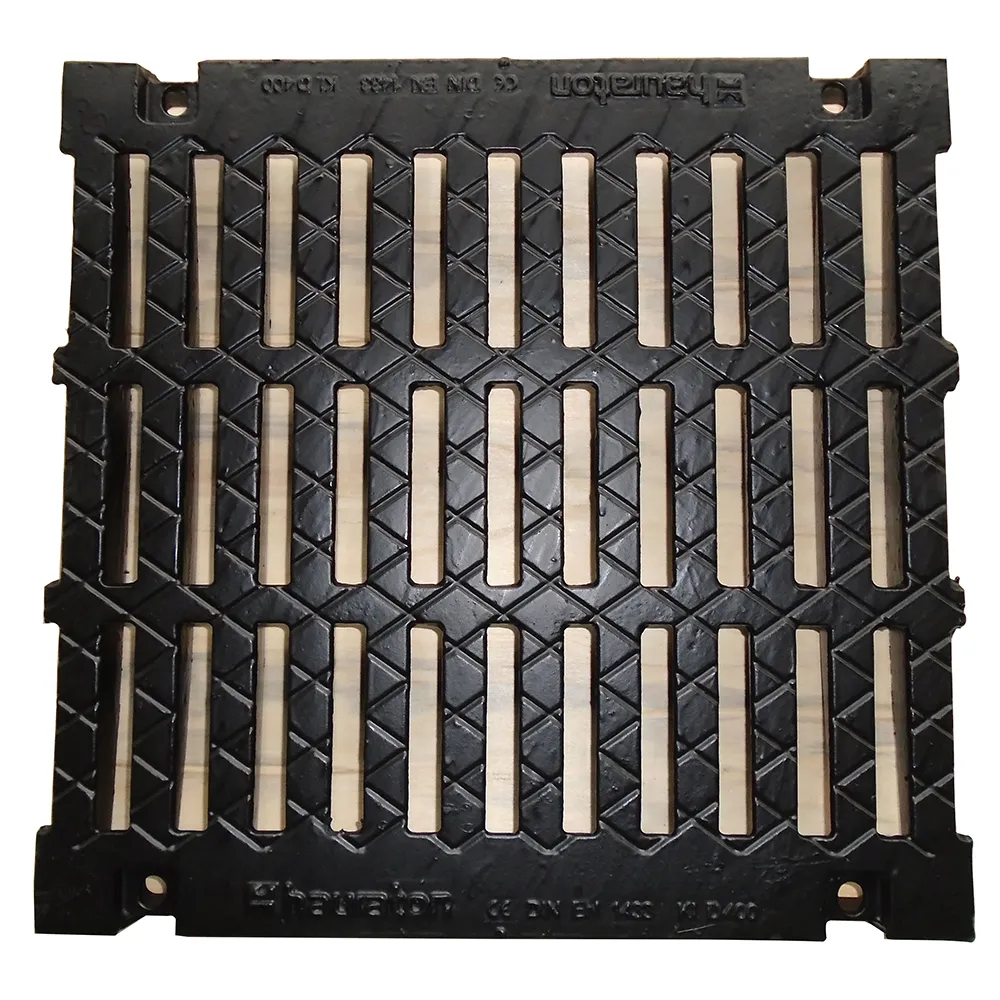

In the realm of urban and industrial infrastructure, the demand for robust and reliable drain covers for sale is escalating, driven by global urbanization, climate change impacts, and a heightened focus on public safety and environmental protection. Modern infrastructure projects, from bustling cityscapes to vast industrial complexes, necessitate advanced solutions for managing subsurface utilities, stormwater runoff, and access points. The industry is witnessing a significant shift towards materials offering superior strength-to-weight ratios, enhanced durability, and improved security features. This evolution encompasses a broad spectrum of products, including heavy-duty municipal manhole covers designed to withstand extreme vehicular loads and specialized storm drain covers for sale engineered for efficient water flow and debris filtration. Technical advancements are also leading to the integration of smart technologies, such as IoT sensors for monitoring fluid levels or structural integrity, positioning drain covers as critical components of intelligent infrastructure networks. The market is increasingly demanding products that not only meet stringent performance criteria but also offer extended operational lifespans and require minimal maintenance, thereby reducing the total cost of ownership for municipalities and private entities alike. Expertise in material science, precision engineering, and adherence to international standards like ISO 9001 and EN 124 are paramount for manufacturers aiming to provide authoritative and trustworthy solutions in this competitive sector, ensuring that every product supplied contributes effectively to the resilience and efficiency of modern infrastructure systems, reflecting a deep understanding of practical application and technical superiority.

Precision Engineering: The Manufacturing Process of Advanced Drain Covers

The production of high-performance drain covers for sale involves a sophisticated multi-stage manufacturing process, primarily utilizing advanced casting techniques, occasionally supplemented by forging or precision CNC machining for specialized components. The material selection is critical, with ductile iron (often GJS-500-7 or GJS-400-15) being a predominant choice due to its superior tensile strength, excellent shock absorption properties, and resistance to impact compared to traditional grey cast iron. The process typically begins with meticulous mold design, followed by sand casting or lost wax casting, ensuring precise dimensions and surface finishes. Molten metal, precisely alloyed and temperature-controlled, is poured into these molds. After solidification, the castings undergo fettling, grinding, and often shot blasting to achieve the desired surface quality. For specialized applications requiring exceptional dimensional accuracy or intricate features, supplementary CNC machining may be employed. Each batch then undergoes rigorous quality control, adhering to international inspection standards such as ISO 9001, ANSI, and specifically EN 124 for manhole covers and gully gratings, which classifies products by load capacity (e.g., A15, B125, C250, D400, E600, F900). This stringent quality assurance ensures product integrity and longevity, extending the typical usage lifespan to 50 years or more under appropriate conditions. These robust products are indispensable across diverse sectors, including petrochemical, where chemical resistance and explosion-proof designs are vital; metallurgy, requiring extreme heat and abrasion resistance; and critical municipal infrastructure for water supply, drainage, and sewage systems. Our municipal manhole covers exemplify these benefits, offering exceptional durability and resistance to corrosion, significantly reducing the frequency and cost of replacements, and demonstrating a commitment to energy saving through efficient system maintenance. Understanding the different types of drain covers and their manufacturing nuances is key to selecting the most suitable solution for any demanding environment.

Technical Specifications and Performance Metrics for Optimal Drain Covers

Selecting the appropriate drain covers for sale requires a deep understanding of their technical parameters and performance characteristics, which are directly correlated with their intended application and environmental stresses. Key specifications include material composition (e.g., ductile iron GJS-500-7 or GJS-400-15), nominal diameter (e.g., 600mm, 700mm, 800mm), clear opening size, frame dimensions, and crucially, the load classification as per EN 124. This standard defines load classes from A15 (15 kN, for pedestrian areas) to F900 (900 kN, for extreme heavy-duty applications like airport runways or dock areas), encompassing B125, C250, D400, and E600 for various road traffic conditions. For example, a D400 class cover is engineered to withstand 40 tons of test load, making it ideal for high-traffic public roads. Beyond load bearing, critical performance metrics include anti-corrosion properties, achieved through advanced coating processes like bitumen painting or epoxy powder coating, and anti-slip surface designs for enhanced safety. The lifespan, often guaranteed for over 50 years with proper installation and maintenance, is a testament to the material integrity and manufacturing precision. These covers find extensive application in petrochemical facilities, where resistance to corrosive chemicals and flame-retardant properties are essential; in metallurgical plants, where high temperatures and heavy industrial loads are common; and predominantly in municipal water, drainage, and sewage systems, ensuring robust and secure access points. The superior design of modern drain covers for sale, including advanced locking mechanisms and sealing features, contributes to significant operational advantages such as reduced water infiltration, minimized odors, and enhanced security against unauthorized access, proving their intrinsic value through their robust technical attributes and long-term reliability.

| Classification | Test Load (kN) | Approx. Test Load (Tons) | Typical Application Areas |

|---|---|---|---|

| A15 | 15 | 1.5 | Pedestrian areas, garden paths, private driveways |

| B125 | 125 | 12.5 | Footways, pedestrian areas, parking decks, light traffic areas |

| C250 | 250 | 25 | Kerbside channels, drainage gratings for roads |

| D400 | 400 | 40 | Roadways (including main roads), hard shoulders, parking areas for all vehicle types |

| E600 | 600 | 60 | Areas subject to high wheel loads, e.g., docks, freight depots, industrial estates |

| F900 | 900 | 90 | Areas subject to exceptionally high wheel loads, e.g., airport runways, port areas |

Strategic Selection: Vendor Comparison and Customization in Drain Cover Solutions

In the complex procurement landscape for infrastructure components, the choice of supplier for drain covers for sale is as critical as the product's technical specifications. A thorough vendor comparison goes beyond initial pricing, encompassing factors such as a manufacturer's adherence to international standards (e.g., ISO, CE, SGS), proven track record, production capacity, and flexibility in customization. Leading manufacturers distinguish themselves through their investment in R&D, offering innovative designs like anti-theft locking systems, ergonomic opening mechanisms, and specialized surface treatments for enhanced durability and safety. Their authoritative position is often cemented by decades of experience, partnerships with major civil engineering firms, and a demonstrable history of successful project deliveries. For instance, the ability to provide bespoke solutions is paramount: whether it's an irregularly shaped access chamber cover for a historical preservation site, a highly corrosive-resistant composite cover for a chemical plant, or a compact mini access chamber cover for residential utility lines, customization ensures perfect fit and optimal performance. Manufacturers who excel in this area often offer services ranging from specific load ratings and dimensions to custom logos and unique color finishes for aesthetic integration. Real-world application cases further highlight this value: a municipal client in a high-traffic urban area might require D400 ductile iron drain covers for sale with advanced anti-theft features, while a utility provider needing access to underground fiber optics would benefit from a secure, lightweight composite cover. Our extensive experience in delivering tailored solutions for diverse global projects, alongside our unwavering commitment to quality and client support, provides a trusted partnership for complex infrastructural needs. This dedication to customized solutions and transparent operational processes enhances trustworthiness and reliability, positioning us as a preferred supplier for discerning B2B clients seeking long-term value.

Ensuring Reliability: Quality Assurance and Support for Drain Cover Investments

The long-term value and reliability of an investment in drain covers for sale are fundamentally underpinned by comprehensive quality assurance protocols and robust customer support. Reputable manufacturers implement multi-stage inspection processes, from raw material verification to finished product testing, ensuring every municipal manhole cover and storm drain covers for sale adheres to strict quality benchmarks like ISO 9001 and EN 124. This commitment to quality is often evidenced by verifiable test data, including load-bearing capacity reports, material composition analyses, and fatigue testing results. Beyond production, client experience is paramount. A transparent delivery cycle, clearly outlining lead times and logistics, builds trust, especially for large-scale infrastructure projects where timely supply is critical. Furthermore, a strong warranty commitment, typically ranging from 5 to 10 years or more depending on the product type and application, signifies a manufacturer's confidence in their product's durability and performance. Exceptional customer support, encompassing technical assistance for installation guidance, ongoing maintenance advice, and rapid response to any post-sales inquiries, significantly enhances the trustworthiness of a supplier. This holistic approach ensures that clients are not merely purchasing a product but investing in a reliable solution backed by expert guidance and unwavering commitment. Satisfied clients, particularly those from long-term partnerships with municipal or industrial entities, often provide testimonials regarding the product's enduring quality and the manufacturer's responsive service, reinforcing the authoritative standing in the market. This comprehensive framework of quality, support, and transparency solidifies the foundation for a truly trustworthy partnership, ensuring that the critical components of public infrastructure are durable, secure, and perform optimally for decades.

Frequently Asked Questions (FAQs)

- Q: What are the primary types of drain covers?

A: Drain covers vary widely, from standard municipal manhole covers designed for heavy traffic to specialized storm drain covers for sale engineered for effective stormwater management. Different types of drain covers cater to specific load requirements and environmental conditions, including round, square, and rectangular designs, often made from ductile iron, cast iron, or composite materials. - Q: How do load classifications (e.g., A15, D400) impact my choice of drain covers for sale?

A: Load classifications, such as A15 for pedestrian areas up to F900 for airport runways, are critical. They indicate the maximum weight a cover can safely bear according to EN 124. For instance, a D400 classification is suitable for roadways, ensuring durability and safety under vehicular traffic. Selecting the correct classification prevents structural failure and ensures long-term performance and compliance. - Q: Can I get customized drain covers to meet specific project requirements?

A: Absolutely. Many manufacturers offer bespoke customization for drain covers, including unique dimensions, specific load ratings, anti-slip patterns, branding (logos), and specialized locking mechanisms. This ensures that the drain covers integrate seamlessly into your infrastructure project, whether it's an access chamber cover for a utility vault or a mini access chamber cover for residential use, demonstrating a high level of engineering experience. - Q: What is the expected lifespan of high-quality drain covers?

A: The lifespan of quality drain covers, particularly those manufactured from ductile iron using advanced casting processes, can extend for decades, often exceeding 50 years under normal operating conditions. Factors influencing longevity include material quality, proper installation, environmental exposure (corrosion, temperature fluctuations), and adherence to specified load limits. Regular inspection and maintenance also play a crucial role in maximizing operational life. - Q: What support is provided after purchasing municipal manhole covers?

A: Reputable suppliers offer comprehensive post-purchase support, including technical assistance for installation, guidance on maintenance, and a robust warranty program. This commitment to customer service ensures that clients receive ongoing value and peace of mind, reinforcing the trustworthiness of the supplier throughout the product's operational life. Our service includes detailed product documentation and accessible expert consultation.

References

- EN 124: Gully tops and manhole tops for vehicular and pedestrian areas – Design requirements, type testing, marking, quality control. European Committee for Standardization.

- International Organization for Standardization (ISO) 9001: Quality management systems – Requirements.

- The Ductile Iron Pipe Research Association (DRIPRA). Engineering design and construction of ductile iron pipelines.

- American Society for Testing and Materials (ASTM) Standards for Gray and Ductile Iron Castings.